Wood chip dryers are essential in the biomass and wood processing industries, preparing raw materials for applications such as wood pellet production, particleboard manufacturing, and biomass fuel generation. Among the notable advancements in this sector, multi-pass technology has emerged as a significant innovation that greatly enhances the drying efficiency of wood chip dryers. This article examines how multi-pass technology improves the drying process, its advantages, and its influence on overall wood chip drying operations.

Understanding Multi-Pass Technology

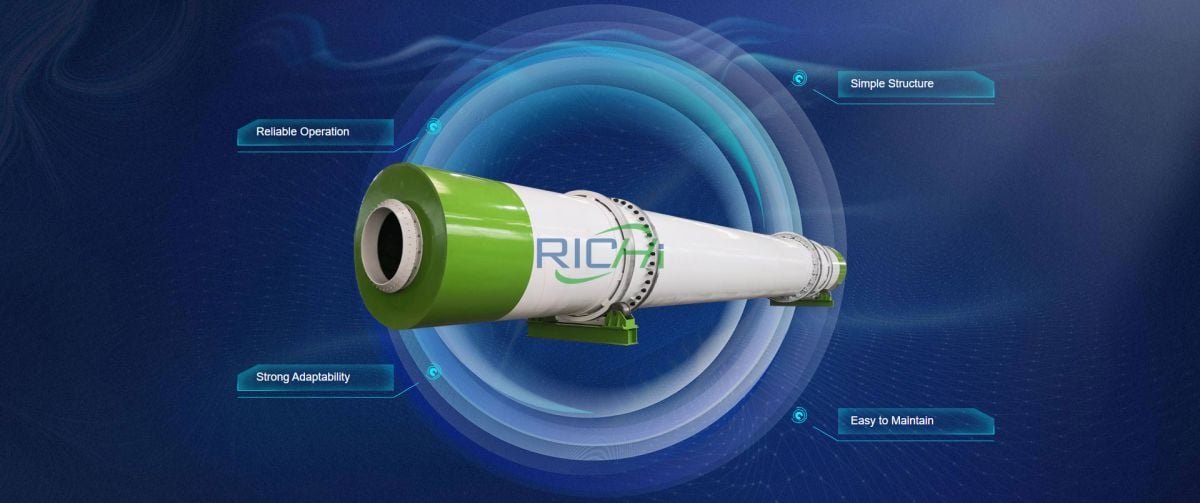

Multi-pass technology in wood chip dryers involves a design where the material being dried makes multiple passes through the drying chamber before it exits. This contrasts with single-pass systems, where the material only travels through the dryer once. In a multi-pass system, the wood chips are repeatedly lifted and showered through a hot air stream within a rotating drum, allowing for extended exposure to drying conditions.

How Multi-Pass Technology Enhances Drying Efficiency

Increased Drying Duration Without Expanding Footprint

One of the key benefits of multi-pass technology is its ability to prolong the drying duration without significantly increasing the dryer’s physical size. By allowing wood chips to make multiple passes through the drum, they spend more time in contact with hot air, resulting in more effective moisture removal. This is particularly advantageous in scenarios where space is limited or extending a single-pass dryer’s length is impractical. (Related post: mesh dryer)

Enhanced Heat Transfer

Multi-pass systems improve heat transfer efficiency by consistently exposing wood chips to hot air. As the drum rotates, the material is lifted and falls through the air multiple times, increasing the surface area exposed to the drying medium. This repeated exposure ensures that all parts of the wood chips, including those that may be sheltered in a single pass, have sufficient opportunities to interact with the hot air.

Improved Moisture Consistency

Achieving uniform moisture content throughout a batch of wood chips can be challenging. Multi-pass technology mitigates this issue by providing multiple chances for each piece of material to be exposed to drying conditions. This repeated exposure helps balance moisture differences among individual chips, resulting in a more consistently dried product.

Flexibility in Drying Parameters

Multi-pass systems offer enhanced flexibility in adjusting drying parameters. Operators can fine-tune aspects such as drum rotation speed, airflow rate, and temperature to optimize the drying process for different types of wood chips or varying initial moisture contents. This adaptability allows for more precise control over the final moisture content of the product.

Energy Efficiency

Although it may seem counterintuitive, multi-pass dryers can be more energy-efficient than single-pass models. The ability to adjust residence time and drying conditions precisely means that energy is used more effectively. Additionally, improved heat transfer efficiency can lead to lower overall energy consumption per unit of moisture removed.

Reduced Risk of Over-Drying

Over-drying can significantly affect wood chip processing, leading to quality issues and unnecessary energy use. Multi-pass systems, with their enhanced control capabilities, allow operators to more accurately target the desired final moisture content, minimizing the risk of over-drying.

Handling Variable Input Materials

Wood chip dryers often deal with materials that have varying initial moisture contents. Multi-pass technology is particularly effective in managing this variability. The multiple passes through the drying chamber create a more forgiving process capable of effectively drying materials with a range of starting moisture levels.

Case Study: Vina Nha Trang’s Multi-Pass Wood Chip Dryers

Vina Nha Trang, a leading manufacturer of wood processing equipment, offers wood chip drying systems that utilize multi-pass technology. Their systems are designed to evaporate up to 9,000 kg of water per hour, demonstrating the high efficiency achievable with this technology. The multi-pass design enables their dryers to handle wood chips with initial moisture contents of 45-50%, consistently achieving a final moisture content of 12 ± 2%.

Key features of Vina Nha Trang’s multi-pass dryers include:

- Drum lengths of 15-18 meters and diameters of 3.2-4 meters, providing ample space for multiple passes

- Capacities ranging from 6,000 to 14,000 kg/h of dried output

- Automated PLC control systems for precise management of drying parameters

- Advanced safety features including temperature and spark sensors to prevent fire hazards

Implementing Multi-Pass Technology: Considerations and Best Practices

While multi-pass technology offers significant advantages, successful implementation requires careful consideration:

Material Characteristics

The characteristics of the wood chips being dried, including size, initial moisture content, and physical properties, should guide the design and operation of the multi-pass system.

Energy Source

The choice of energy source for heating (e.g., natural gas, biomass, or electricity) can affect the overall efficiency and environmental footprint of the drying operation.

Integration with Existing Systems

When upgrading to a multi-pass dryer, it is essential to consider how it will integrate with existing material handling and processing equipment.

Maintenance Requirements

Multi-pass systems may have more moving parts or complexity compared to single-pass dryers. Establishing a comprehensive maintenance program is crucial to ensure long-term reliability and efficiency.

Operator Training

Effective use of multi-pass technology requires operators to understand how to optimize the system for different drying scenarios. Investing in thorough training programs is vital.

Conclusion

Multi-pass technology represents a substantial advancement in wood chip drying efficiency. By allowing for increased drying time without expanding the dryer’s footprint, enhancing heat transfer, improving moisture consistency, and offering greater flexibility in process control, multi-pass systems effectively address many challenges associated with traditional single-pass dryers.

As the demand for efficiently processed wood chips continues to grow in industries ranging from bioenergy to wood products manufacturing, the adoption of multi-pass drying technology is likely to increase. Manufacturers like Vina Nha Trang are at the forefront of this trend, offering systems that leverage multi-pass technology to achieve high efficiency and product quality.

For operators considering an upgrade to their wood chip drying capabilities, multi-pass technology provides a compelling solution that can enhance product quality, reduce energy consumption, and improve overall operational efficiency. As with any significant technological investment, careful analysis of specific operational needs and conditions is essential to fully realize the benefits of this innovative drying approach.