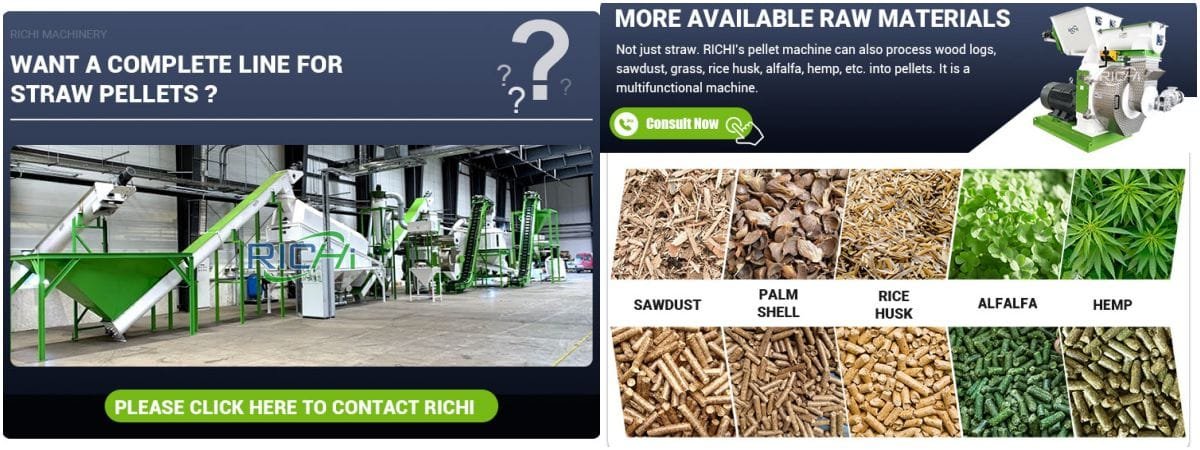

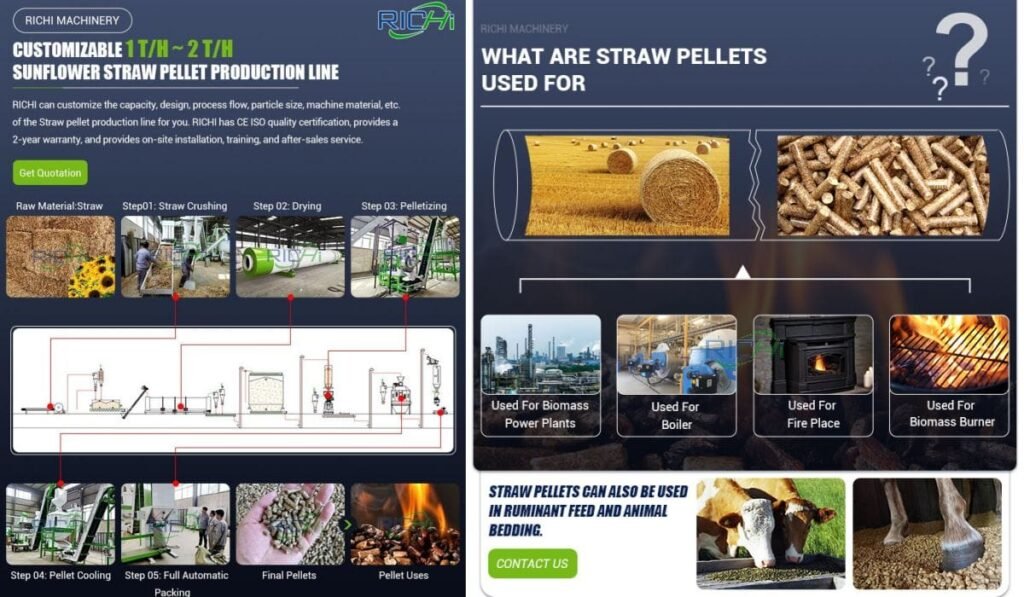

The Straw Pellet Production Line, primarily designed for processing straw into pellets, is highly adaptable and can produce a variety of other biomass pellets. This versatility makes it a valuable asset for farmers, renewable energy producers, and businesses looking to diversify their product offerings or utilize different agricultural and forestry residues. Here’s a look at the range of biomass types that can be produced using a Straw Pellet Production Line.

Types of Biomass Pellets

- Wood Sawdust Pellets:

- Description: Processed from sawdust, a byproduct of wood processing.

- Uses: Suitable for residential heating, industrial boilers, and power generation. Known for high energy content and clean-burning properties.

- Wood Chip Pellets:

- Description: Made from wood chips from forestry operations or wood processing.

- Uses: Useful for large-scale heating systems, co-firing in power plants, and industrial process heat.

- Bamboo Waste Pellets:

- Description: Produced from bamboo processing waste, including leaves and small branches.

- Uses: High calorific value, rapid renewability, and low ash content make these pellets valuable for energy production.

- Rice Husk Pellets:

- Description: Made from rice husks, a byproduct of rice milling.

- Uses: Valuable for biomass power plants, industrial heating, and as a soil amendment.

- Corn Stalk Pellets:

- Description: Created from corn stalks left after harvesting.

- Uses: Suitable for animal bedding, biomass fuel, and soil amendment. (Related post: corn stalk pellet machine)

- Soybean Stalk Pellets:

- Description: Produced from soybean stalks.

- Uses: Useful for livestock bedding, fuel in biomass boilers, and organic mulch in agriculture.

- Cotton Stalk Pellets:

- Description: Made from cotton stalks, typically considered waste.

- Uses: Suitable for industrial heating and power generation, as well as soil improvement.

- Sunflower Stalk Pellets:

- Description: Produced from sunflower stalks.

- Uses: Useful for residential heating, industrial boilers, and as a component in animal feed.

- Peanut Shell Pellets:

- Description: Made from peanut shells, a byproduct of peanut processing.

- Uses: Suitable for biomass fuel, animal bedding, and organic fertilizer.

- Grass Pellets:

- Description: Produced from various grasses, including lawn clippings and dedicated energy crops.

- Uses: Used for heating in pellet stoves, animal bedding, and as a soil amendment.

- Olive Pomace Pellets:

- Description: Made from olive pomace, the solid remains after olive oil extraction.

- Uses: High-energy biomass fuel and organic fertilizer or soil conditioner.

- Bagasse Pellets:

- Description: Created from sugarcane bagasse, the fibrous matter remaining after juice extraction.

- Uses: Fuel in sugar mills, power generation, and as a renewable fuel source in various industries.

- Coffee Husk Pellets:

- Description: Made from coffee husks in coffee-producing regions.

- Uses: Renewable fuel source and potential use as organic fertilizer.

- Coconut Shell Pellets:

- Description: Produced from coconut shells, often considered waste.

- Uses: High-energy biomass fuel and activated carbon production, as well as landscaping materials.

- Palm Kernel Shell (PKS) Pellets:

- Description: Made from palm kernel shells in palm oil-producing regions.

- Uses: Known for high calorific value and suitability for industrial heating and power generation.

Advantages of Using Straw Pellet Production Line for Various Biomass

- Versatility: The ability to process a wide range of materials allows for adaptation to local agricultural and forestry conditions and available resources.

- Waste Reduction: Converting various agricultural and forestry residues into pellets helps reduce waste and create value from byproducts.

- Renewable Energy Production: Many biomass pellets serve as renewable energy sources, contributing to sustainable energy goals.

- Improved Material Handling: Pelletizing various biomass materials enhances their density, making storage, transportation, and use more efficient.

- Market Diversification: The ability to produce different types of biomass pellets enables businesses to cater to various markets and applications.

- Year-Round Production: By processing different materials, the production line can operate throughout the year, maximizing equipment utilization.

Considerations for Producing Different Biomass Types

While the Straw Pellet Production Line is adaptable, certain considerations must be taken into account when producing various biomass types:

- Die Specifications: Different materials may require changes in die specifications for optimal pellet formation.

- Moisture Content: Varying moisture levels in different biomass materials may necessitate adjustments in the drying or conditioning process.

- Grinding Requirements: Some materials may need finer or coarser grinding compared to straw for effective pelletization.

- Binding Properties: Certain biomass types might require the addition of natural binders to ensure pellet integrity.

- Energy Content Analysis: Regular testing is crucial to ensure that the pelletized biomass meets the intended energy content for its application.

- Ash Content Management: Different biomass types produce varying amounts of ash when burned, affecting their suitability for certain applications.

Conclusion

The Straw Pellet Production Line showcases remarkable versatility in producing a wide range of biomass pellets. From agricultural residues to forestry byproducts, this production line offers the flexibility to create diverse biomass products tailored to different energy needs and local resource availability.

This adaptability maximizes equipment utility and creates value-added products from materials that might otherwise be considered waste. By enabling the production of multiple biomass types, the Straw Pellet Production Line becomes a valuable tool in promoting circular economy principles and sustainable resource utilization.

As the demand for renewable energy sources and sustainable waste management solutions continues to grow, the versatility of equipment like the Straw Pellet Production Line will play an increasingly important role. It offers a practical solution for converting a wide array of biomass materials into standardized, easy-to-use pellets, contributing to both waste reduction and renewable energy production goals.