Initiating a poultry feed manufacturing plant can range significantly in cost, with small-scale operations starting around $20,000 to $30,000, and large-scale, fully automated plants potentially reaching upwards of $2 million. This variance is a reflection of the diverse requirements and capacities within the industry, making the “poultry feed manufacturing plant cost” a critical consideration for investors and entrepreneurs looking to tap into the lucrative poultry feed market.

Industry Use and Data Analysis

The agricultural sector’s backbone, the poultry industry, is currently experiencing an insatiable demand for quality feed, propelled by the global increase in poultry product consumption. Market analysis forecasts a steady growth in the poultry feed market, with expectations to expand at a Compound Annual Growth Rate (CAGR) of over 4.5% from 2021 to 2026. This anticipated growth underscores the vital role of efficient poultry feed manufacturing plants in ensuring sustainable poultry production.

Classification and Working Principle

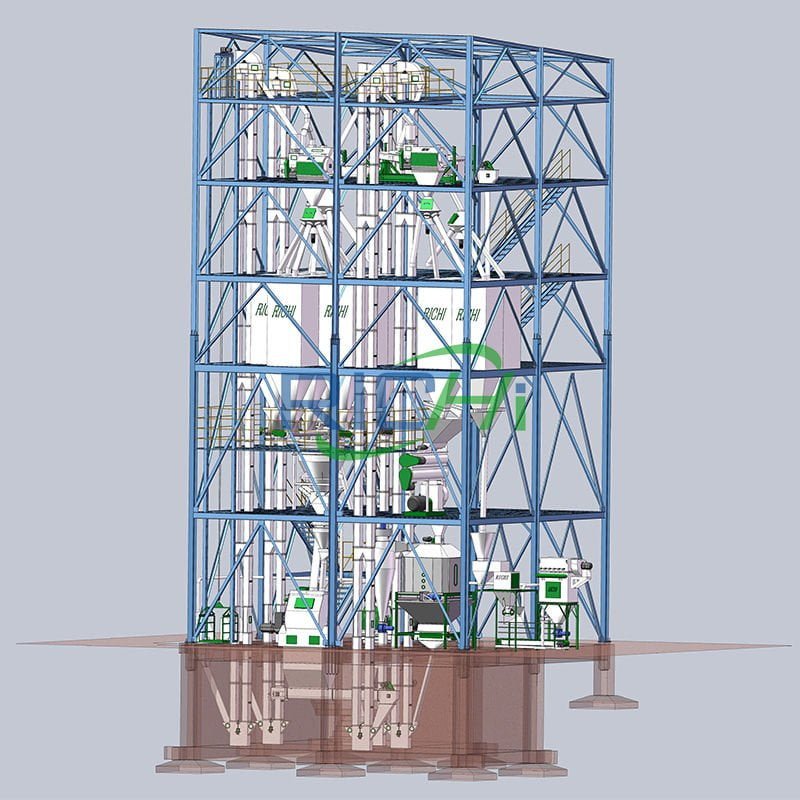

Poultry feed manufacturing plants are broadly classified based on scale and automation:

- Small to Medium Scale Plants: Tailored for local or regional demands, these facilities often employ semi-automation.

- Large Scale Plants: Designed for mass production with full automation, catering to extensive poultry operations and export needs.

The production process in these plants follows a comprehensive workflow:

- Raw Material Handling: Gathering and preparing grains, proteins, and other feed components.

- Mixing: Blending the ingredients to achieve a balanced nutritional profile.

- Pelleting: Compressing the mix into pellets, enhancing feed efficiency.

- Cooling and Packaging: Finalizing the product for distribution.

Choosing the Right Plant and Supplier

Determining the appropriate plant involves assessing several factors, such as capacity, technological advancements, and cost efficiency. Real-world scenarios highlight the importance of custom solutions, which align with specific operational objectives for enhanced efficiency.

Richi Machinery Company of Henan, China, exemplifies excellence in customizing pellet production lines for poultry feed manufacturing. Their adeptness in designing solutions tailored to the unique needs of their clients ensures optimized operations. Richi Machinery’s commitment to innovation and customer satisfaction positions them as a leading choice for those investing in the sector.

Practical Application Value

Investment in a poultry feed manufacturing plant offers:

- Custom Nutrition: Facilitates tailored feed production for various poultry needs.

- Operational Efficiency: Modern technology reduces costs and increases output.

- Competitive Edge: Quality feed improves poultry health, boosting market performance.

FAQs on Poultry Feed Manufacturing Plant Cost

What are the primary cost drivers for establishing a poultry feed plant?

Key factors include production capacity, automation level, equipment quality, and feed formulation complexity.

Are there cost-effective solutions for small-scale farmers?

Yes, options exist for smaller, more affordable setups, with potential financial aids making these investments more accessible.

How does supplier choice affect plant cost and efficiency?

Choosing a reputable supplier like Richi Machinery ensures efficient operations and a better return on investment through high-quality equipment and reduced operational disruptions.

What ongoing operational costs should investors anticipate?

Considerations include raw materials, maintenance, labor, and energy consumption.

In summary, the venture into poultry feed manufacturing is a substantial investment that demands thorough analysis and strategic planning. By partnering with experienced suppliers such as Richi Machinery, entrepreneurs can navigate the complexities of the market, ensuring a profitable and sustainable entry into the poultry feed industry.